Welcome to Arganfarm, and to our step-by-step guide to how is Argan oil made.

If you’re a fan of all-natural beauty products, chances are you already came across Argan oil at some point.

Pure Argan oil, also known as oil from Morocco or “liquid gold” (Note: Not brands containing the wording “Moroccan” or “from Morocco” as that doesn’t necessarily mean that it’s genuine or pure Argan oil!), is a luxurious and highly sought-after natural oil used to solve a wide variety of skin, hair, and many beauty issues and it’s hence known for its numerous benefits for overall health and beauty from head to toe.

Extracted from the Argan fruit nut (kernel) of the Argan tree, which is native to Morocco and found exclusively in the southwestern region of the country, this oil has been used for centuries by locals (especially in the south of Morocco) for its nourishing and protective properties.

In recent years, Argan oil gained much popularity around the world and is now found in a myriad of beauty and wellness products.

But have you ever stopped to wonder how is Argan oil made and consider the journey that a single drop of pure Argan oil takes before it ends up in a bottle on the store shelves?

In this blog post (first part), we’ll be taking a closer look at the first steps of how pure Argan oil is made: The harvesting and the Argan kernels’ extraction processes.

In the subsequent parts of the “how is Argan oil made” blog post series (which is linked at the bottom of this page), We’ll be exploring the traditional techniques and the modern methods used to extract the final product, the crucial role women play in the the production of Argan oil, as well as the importance of sustainability in how Argan oil is produced and much more.

So join us as we take a trip “from tree to bottle” and discover the story behind this precious oil. Here are the key points we’ll cover:

- Why question how is Argan oil made?

- The Argan tree and its fruits

- How is Argan oil made: Drying, cracking and the kernel’s extracting

- Introduction to pure Argan oil production

- How is Argan oil made: The harvesting

- A few stats on how is Argan oil made

Why the question how is Argan oil made?

Many (if not the majority) of the Argan oil newcomers, often fall into the “comparing-prices-only” trap, while trying to buy Argan oil, the wonderful product they heard and/or read so much positive reviews about, only to realize (usually after a few orders from different sources offering an allegedly bargain Argan oil deal), that the product they are really after has its justifiably higher price tag.

Don’t get me wrong here,

it is not the clients’ nor the readers’ fault if they fall into such a trap. It isn’t easy to sort through the fluff about Argan oil out there and let’s not talk about the lack of reliable information in the first place.

So I hope this post will enable you to see Argan oil from the perspective of the hard-working women who sit each & every day to process this liquid gold and hence give you a clearer idea on how is Argan oil made, the intense, cumbersome and time-consuming steps that all go into producing traditional & pure organic Argan oil.

The Argan oil (or oleo de Argan, and huile d’argan) is produced from the seeds extracted out of the Argan nuts with varying yields depending on the extraction method as well as on the quality of the Argania Spinosa kernels used.

A brief introduction to pure Argan oil production

When we ask people about how is Argan oil made, many people have no (or only a vague) idea that the production of Argan oil is a labor-intensive process that involves several steps, from harvesting the fruits to extracting and refining the oil.

In the past, the production of Argan oil was done entirely by hand using traditional techniques. However, modern methods such as machine cold-pressing have also been introduced to streamline the process.

In recent years, the production of Argan oil has also generally become more sustainable, with an emphasis on eco-friendly practices and fair labor. But before we get to the first step, which is harvesting, let me give you a brief overview about the Argan tree itself:

The Argan tree and its fruits

The Argan tree (Argania, or Argania spinosa – Tashelhit / Berber: ⴰⵔⴳⴰⵏ Argan) is a slow-growing tree endemic to the calcareous semidesert Souss valley of southwestern Morocco as well as to the region of Tindouf in southwestern Algeria, and is well-adapted to the dry, arid climate of those regions. Please note however that the Argan trees that grow in the Tindouf region bear no fruits, as opposed to those that grow in Morocco.

With a lifespan of up to 200 years, the Argan trees can grow up to around 8 to 10 meters (26 – 33 ft) in height, have twisted, gnarled trunks with thorny stems and small green leaves that are 2 to 4 cm (0.79 – 1.57 in) long, and produce small, pale yellow-green flowers that start blooming around April.

Argania Spinosa’s small yellow-green fruits take six months to almost a year to ripen and are typically harvested between July and August. The fruit’s size is about 2 to 4 cm (0.79 – 1.57 in) long and 1.5 to 3 cm (0.59 – 1.18 in) wide. It has a thick, bitter outer peel and a sweet-smelling pulp with an unpleasant taste.

Inside the fruit is a hard nut that contains one (but occasionally even two or three) small seeds/kernels that are rich in oil.

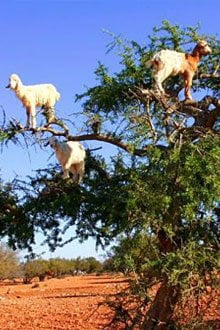

This makes the Argan tree not only an important source of food and shelter for a variety of animals (including goats, which are known for climbing the trees to eat the fruits), but also an important source of income for the local population thanks to the Argan oil sales revenue.

In addition to its economic and ecological importance, the Argan tree is also culturally significant to the people of Morocco and it’s considered a symbol of resilience as it is revered for its ability to thrive in difficult climatic conditions.

How is Argan oil made: The harvesting

The production of Argan oil begins with the harvesting of the fruit from the Argan tree.

Apart from the environmentally questionable mechanical harvesting methods introduced in the last two decades, there are 3 traditional ways of collecting Argan fruits which have been practiced by locals here for centuries:

- The women would either collect the fruits after they fall from the tree late July and beginning of August.

Goats climbing the Argan tree. - OR collect the Argan nuts that goats spit out after they ruminate and eat the fleshy part (pulp) of the fruit.

- OR pick the Argan fruits by hand directly from the trees. This is usually requires a lot of patience, tolerance for scratchers due to the thorny nature of the stems, and in many cases the use of ladders to reach the Argan fruits at the top of the trees. (in some cases and in absence of ladders, the women would fell the rest of the Argan fruits using stones).

No worries: the second one is cleaner and safer than it sounds because:

- – the kernels are protected in a bullet-proof shell

- – and the uncracked Argan nuts are treated clean before any further processing.

Besides, remember the most expensive coffee in the world – ≈ 400 $ a cup- is made from animal poop! In the case of Argan oil however, the oil made from fruits collected by goats is of a lower quality and potency.

The goats of the Argan tree regions acquired amazing climbing skills to reach and nourish on their favorite food: the Argan fruits, and thus “helping” in the harvesting process by cleaning up the unreached fruits 🙂

Using the fruits collected by goats to produce Argan oil however is becoming more and more rare though, as the cooperatives’ raw material needs are much higher than what any goat herd can provide.

How is Argan oil made: Drying, cracking and kernels’ extraction

After being hand-collected or directly harvested, the Argan fruits are either dried in the open air and sun for a few weeks to help remove the fleshy pulp (which is used as very nutritive animal feed) or the pulp is removed mechanically to save time before starting one of the different extraction processes.

After that, the Argan kernels, which are surrounded by a hard shell, must be extracted before processing them to extract Argan oil. The kernel extraction can be done in two ways:

– The traditional way by crushing the hard shells with a stone (low kernel extraction yield per hour, but the end product has a superior quality).

– With a modern machine (high kernel extraction yield per hour, but lower quality end product – I will explain why subsequently!).

One important factor to note when it comes to extracting the Argan kernels, is that they start oxidizing as soon as they come in contact with air. And the longer they remain in contact with air, the more they oxidize and the higher the negative impact this will have on the end product’s quality and potency. In other words, the quicker the kernels are processed after extraction, the higher the quality and potency of the end product.

This brings us to the issue with the machine kernel extraction: The Argan kernel extraction machines slam the Argan nuts with such a high velocity against a hard -usually metallic- surface (think of a bullet shot against a steel wall), that the entire nut including the kernels is scattered into multiple pieces.

This offers a wider attack surface for oxidation (since multiple crumbs / pieces) as opposed to a whole / intact kernel, which impacts the kernel’s quality and consequently the end product’s potency as well as its shelf-life.

Once the kernels are extracted, the next step in how Argan oil is made depends on which version of Argan oil one intends to produce: The cosmetic Argan oil, or the culinary one.

To yield cosmetic Argan oil (aka. cold-pressed), the kernels are pressed naturally without roasting etc. and hence the oil has an almost-neutral smell (shelf-life of a sealed cosmetic Argan oil container: minimum 24 months).

To yield the culinary version however, the kernels are roasted on open fire to bring out the nutty flavor (+ the nutty smell) and aroma, before being pressed (shelf-life of a sealed culinary Argan oil container: minimum 12 months).

Note: In a few cases, culinary Argan oil can be also used for cosmetic purposes, however only for light issues, as it is less potent due to the roasting process of the kernels.

A few stats on how Argan oil is made

The time as well as the quantity of the Argan fruits needed to gain 1 liter of the precious pure Argan oil depend on the extraction method used as well as on the crop quality:

- It takes ≈ 2 Kg of the Argan kernels which equals ≈ 25-30 Kg of Argan fruits.

- It can take 2 days of hard work to remove the dried pulp & crack ≈ ½-2 Kg of nuts (kernels) for the same amount of pure Argan oil.

- In the case of culinary Argan oil, it takes ≈ 30 minutes to roast the 2 Kg needed.

- The cumbersome process of grinding the 2 Kg of roasted Argan kernels, takes between 2½ & 3 hours.

By the way the seasonal average fruit crop yield per Argan tree is 120 to 180 kg depending on the weather as well as the quality and kind of ground around it.

When it comes to how is Argan oil made, the lengthy process and the rareness of the tree are 2 of the inescapable factors influencing the price of the real and pure Argan oil.

To have a better understanding of the different Argan oil extraction methods, please click here!

How is Argan oil made: The different Argan oil extraction methods

1 comment

Emma

Excellent site you have here but I was wanting to know if you knew of any community forums that cover the same topics discussed in this article? I’d really like to be a part of community where I can get advice from other experienced people that share the same interest. If you have any suggestions, please let me know. Many thanks!|